In the pharmaceutical industry, freeze-drying technology is widely used to prepare drugs such as biological products, vaccines, antibiotics, hormones, and enzyme preparations. Because the characteristics of these drugs are easily affected by environmental factors such as heat and humidity, the use of freeze-drying technology can greatly maintain the effective ingredients and therapeutic effects of the drugs.

Medical freeze-drying machines have certain applicability and flexibility in handling various forms of drugs, which can help pharmaceutical manufacturing enterprises better maintain the active ingredients of drugs, extend the storage time of drugs, improve the stability and dissolution rate of drugs, and better meet the quality needs of medical institutions and patients.

What are the operating techniques for pharmaceutical freeze-drying machines

Equipment preparation: Before using the medical freeze-drying machine, it is necessary to inspect and prepare the equipment. Check if the equipment is functioning properly, if there is any damage, and ensure that it is in good working condition.

Sample preparation: Before performing freeze-drying operations, it is necessary to prepare the sample to be processed. Ensure that the quality and quantity of the samples meet the requirements, and the samples should be evenly distributed on pallets to avoid uneven freeze-drying.

Set parameters: Based on the characteristics and requirements of the sample, set the parameters of the pharmaceutical freeze-drying machine, including temperature, pressure, time, etc. The setting of these parameters has a significant impact on the quality of the final product and needs to be adjusted according to the actual situation.

Turn on the device: According to the set parameters, start the medical freeze-drying machine and wait for the device to reach the working temperature and pressure. Before the formal freeze-drying operation, ensure that the equipment operates stably and there are no abnormal situations.

Freeze drying operation: Place the prepared sample on the tray of the pharmaceutical freeze-drying machine and operate according to the equipment's workflow. During the freeze-drying process, it is necessary to monitor the working status of the equipment to ensure that the sample is freeze-dried under appropriate conditions.

The main advantage of pharmaceutical freeze-drying machines is that they can process drugs into dry powder while maintaining their original characteristics, thereby improving the stability and shelf life of drugs, and also facilitating the transportation and use of drugs. In addition, freeze-dried drugs are lightweight, small in size, easier to store and transport, and convenient for carrying and application.

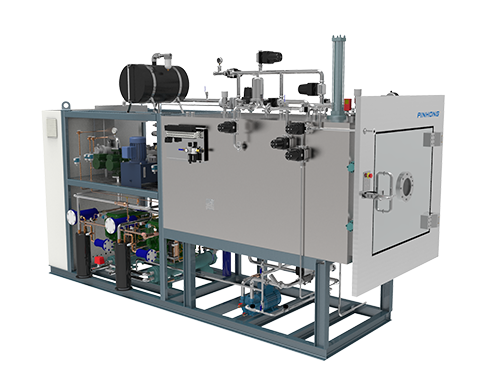

The medical freeze-drying machine is mainly composed of sampling device, host, pump group, pressure reducing system, heating system, cooling system, cleaning system, and other parts. The working principle is to first put the drug into a freeze-drying machine, freeze the drug into a solid in a low-temperature environment, and then directly sublimate the water from the solid state to the gas state through a pressure reducing system, thereby removing the water and finally obtaining the freeze-dried drug.

130 8413 3386

Tel:0411-87935556

E-mail:dlpinhong@163.com

Address:No. 1, building 8, Hongxing Industrial Park, Dalian Economic and Technological Development Zone, Dalian

More highlights are waiting for you